Home > Products > Pro Series > ZM-W100

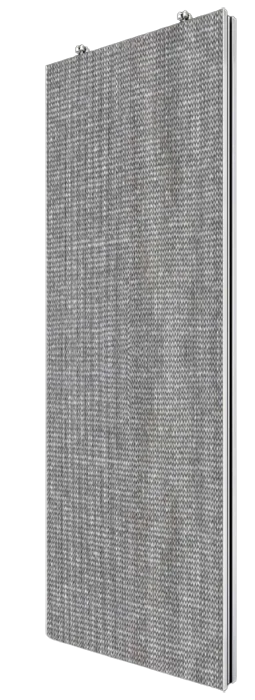

The Acoustic 100 movable wall system can create silence with a panel thickness of only 107mm. It is extremely easy to operate and completely user friendly. There are no limits on parking layouts and countless design surfaces to choose from.

As with the name, Acoustic 100 can provide sound insulation up to 55 dB. The height of walls can be up to 15 meters. The standard panel width is 1200mm, but the wide panels of more than 2000mm are often produced on special request without any problem. Single or double pass doors can be integrated into acoustic 100 walls. if required, fire resistant panels can be produced as custom solutions.

Surface finishes such as fabric, laminate, veneer, wall paper and Acoustic board etc.

Rockwool plain slab of 96 kg/m3 density, 50mm thickness will be used for stuffing in between the two MDF boards of each panel for acoustic performance of the panel.

Extra acoustic dB level will be use in bitumen acoustic matt.

Track & Roller arrangement with Panel suspension

The Acoustic 100 is a movable wall system hung from a top track, without floor guides Every panel is suspended by one, or two, trolleys which run in an aluminium ceiling track. These maintenance free trolleys are of a multiple ball bearing type Roller.

Panel Construction

The panels are constructed around an aluminium/MS frame anti-rust coated, on both sides of which 16mm thickness MDF boards are acoustically free hung. Panel-thickness is ± 107 mm Acoustic ratings available from STC 56 ( 55dB) & STC 51 ( 50dB). Rock wool 50 mm thk to be use of 96kg/m3 Density insulation in between the Both side 16 mm MDF Board. The aluminium nose and counter profiles ensure tight closure like tongue and groove between the panels by magnetic strips with 55N pressure per linear meter north /south pole and rubber seals. These vertical profiles can be exposed, to give protection to the edges of the panel, or can be inlaid (recessed) so they are not visible when the wall is closed.

Panel Retractable seals

Each panel is provided with a retractable spring tensioned seal at the top and bottom, with a pressure of 1500N. The seals are pressed against the underside of the aluminium track at the top and against the finished floor at the bottom, by manually operating an internal spindle mechanism with Bevel gear system. The seals are aluminium based and designed to overcome small deviations in the floor, to achieve high acoustic values and ensure a rigid closure.

Telescopic panel

The closing panel at the end of the wall is a telescopic adjusting panel. This panel has an internal telescopic section (the suitcase) on one side. This section is built in the same way and of the same materials as the panel. It is operated, together with the top and bottom seals, by an internal three-way spindle mechanism with Bevel Gear. The maximum achievable stroke is approx. 110 mm. The pressure is adjustable .

Pass door panel

Single, or double pass door panels, are constructed with a MS frame anti-rust coated. The frame legs (jambs) incorporate retractable seals for complete and tight closure to the floor. As an option they can be supplied also with a floor bolt and tube. The seals in the frame legs, and at the top of the panel, are manually operated by an internal mechanism. This mechanism also locks the door when the panels are being moved. The bottom seal of the door leaf is automatically activated and can be adjusted to the correct stroke. With a double pass door, one half (the active leaf) is used as a standard door, mortise lock with handles, the other (the passive leaf) has no handles, and normally used only when the active leaf is open.

Panel adjustment and decoration

All panels can be adjusted for height without opening the ceiling, or the panel. In case of surface damage, the face panels can be replaced without removing the panel from the track. Surface boards can be decorated with any type of material, i.e laminates, veneers, cold-rolled steel sheet, fabric, wallpaper and acoustic panels etc.

Baffiling with MS structutre

Sound baffles of above the substructure with 12mm thk plywood/12mm thk gypsum board on either sides of the MS frame work with rock wool of 96kg/m3 Density insulation in between the plywood /gypsum board (Above the false ceiling). Provide around trim as per the architect requirement. The board shall be jointed and finished to have a flushed look by filling and finishing with proprietary supplied jointing tape.

The Acoustic 100 movable wall system can create silence with a panel thickness of only 107mm. It is extremely easy to operate and completely user friendly. There are no limits on parking layouts and

countless design surfaces to choose from. As with the name, Acoustic 100 can provide sound insulation up to 55 dB. The height of walls can be up to 15 meters. The standard panel width is 1200mm,

but the wide panels of more than 2000mm are often produced on special request without any problem.